Success Story BL.Predict x Saint Jean! The objective? Optimize the maintenance of its fresh pasta production! Production line availability, data centralization, migration from corrective to preventive maintenance… Here’s a look back at this collaboration which combines technological innovation and complex manufacturing systems.

La “Maison” Saint Jean, the art of fresh French pasta

History shows that France, like Italy, is a land of fresh pasta… Saint Jean is one of the key players in this market. Born in the heart of the Dauphiné region, raviole is a proud part of France’s gastronomic heritage. Its history dates back to the 13th century, when it was already appreciated in the region for its simplicity and authentic flavors. Made in Romans-sur-Isère and Royans, this local specialty has conquered taste buds over the centuries.

Saint Jean is also the story of a providential meeting between two men with a passion for gastronomy and the French culinary tradition. On the one hand, Emile Truchet, a visionary restaurateur from Romans-sur-Isère, who was looking for a solution to mechanize the time-consuming production of ravioles, and in 1935 invented the raviolatrice. On the other, a descendant of raviole makers, the holder of the precious secret of the original recipe for Veritable Raviole du Dauphiné, a culinary treasure of this region.

A growing production and processing system

Today, the French pasta maker has diversified into other products derived from the production and processing of fresh pasta: ravioli, fresh pasta, gnocchi, crozets, quenelles and ready-made meals. Saint jean has more than 500 employees, 18,000 tons of products in 2023, and the French company represents sales of over 115 million euros, spread over five production sites in Auvergne Rhône Alpes.

The Saint Jean group recently invested 80 million euros in a project to expand its main site in Romans, with the aim of tripling its fresh pasta production capacity from 5,800 tonnes to 15,000 tonnes. From an industrial and environmental standpoint, Saint Jean is also a particularly innovative manufacturer, committed to preserving its home region: eco-design of buildings to reduce energy consumption, solar panels, better valorization of energy produced by installations and recovered by heat pumps, monitoring of its impact on water in a drought-prone region, Centralized Technical Management (CTM) of equipment and collection of most technical parameters via Siemens and Clauger OPCUA PLCs.

The specific challenges of maintenance in the agri-food industry

In the agri-food industry, maintenance is characterized by its particularly high requirements to guarantee safety, cleanliness and compliance. Planning interventions is a key element in minimizing production interruptions and coordinating with cleaning actions. By combining preventive strategies, real-time technical information and technological innovations such as IoT and CMMS, it becomes possible to optimize the necessary operations while complying with sanitary standards. Saint Jean uses CARL BERGER-LEVRAULT’s Carl Source CMMS at all its production sites.

The group has a high density of equipment to control for all its sites: some twenty production lines, sixty Air Handling Units (AHUs), twenty chillers and steam boilers. More specifically, the Romans-sur-Isère site, which covers 8 hectares with 30,000 m2 of buildings, has a total of some forty AHUs. Current maintenance of this equipment is carried out on an almost systematic basis, and monitoring of filter clogging on these AHUs requires particular vigilance.

BL.Predict x Saint Jean: main results

With the aim of always being at the cutting edge and as proactive as possible, Saint Jean decided to test the BL Predict solution as early as 2024 to gain a better understanding of the operation of its power plants, as a complement to its BMS. The tool offers two key advantages:

- Its complementarity with the Carl source CMMS enables automated creation of maintenance interventions, with in particular the use of production ranges, inventory management and resource planning. In this context, a monitoring system for air handling unit filter clogging has been set up. As measurement of the pressure delta on either side of the filter was unfortunately unavailable, monitoring focused on tracking drive power and/or the percentage of fan operation.

- The tool also enables longer-term analysis processing than the BMS can perform: equipment comparison, multi-parameter analysis, creation of additional indicators, anomaly detection, integration of contextual data such as weather, or data from external suppliers: energy, fluids, energy reporting.

Automation and prevention of maintenance

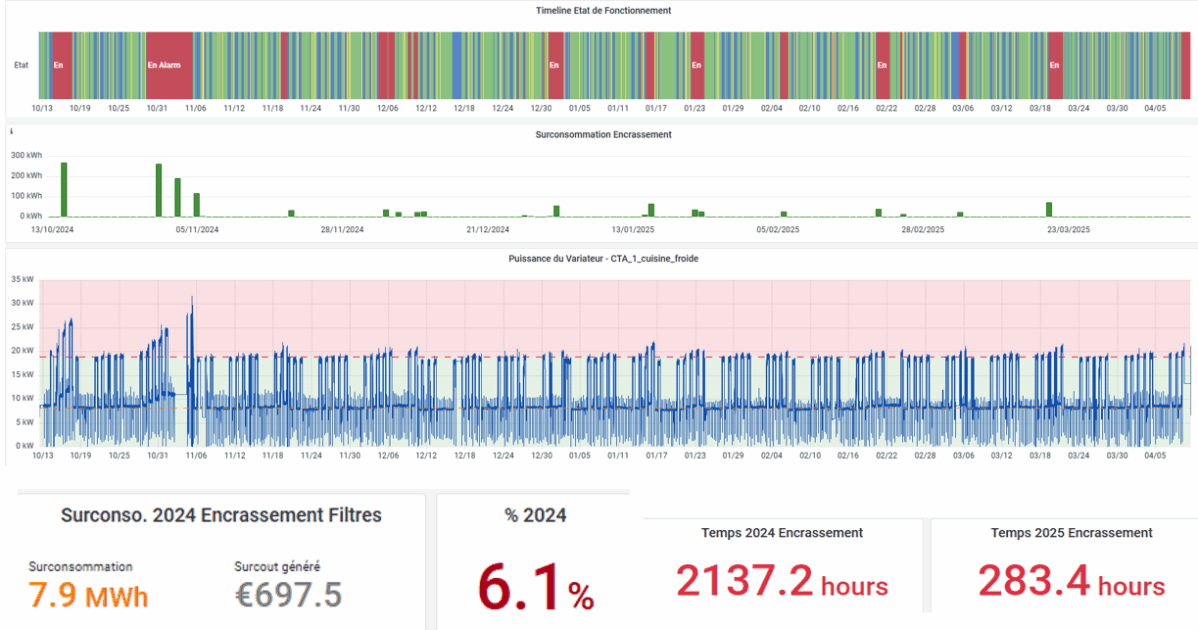

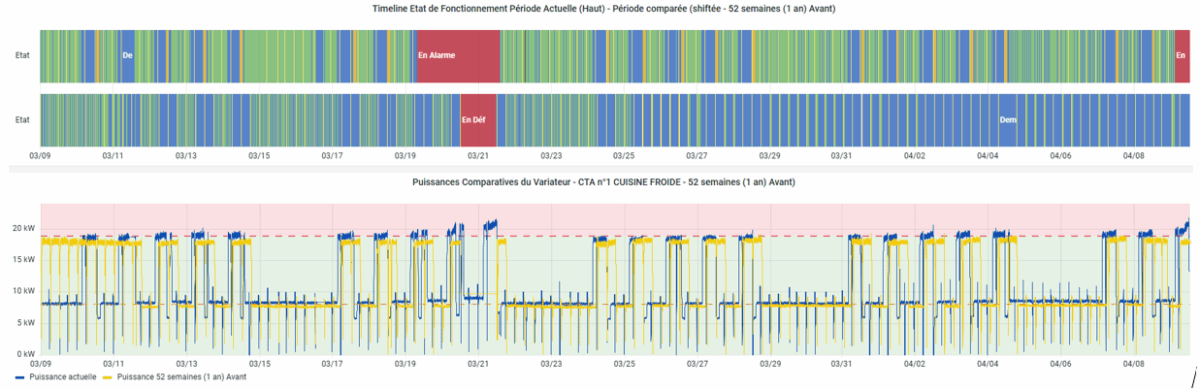

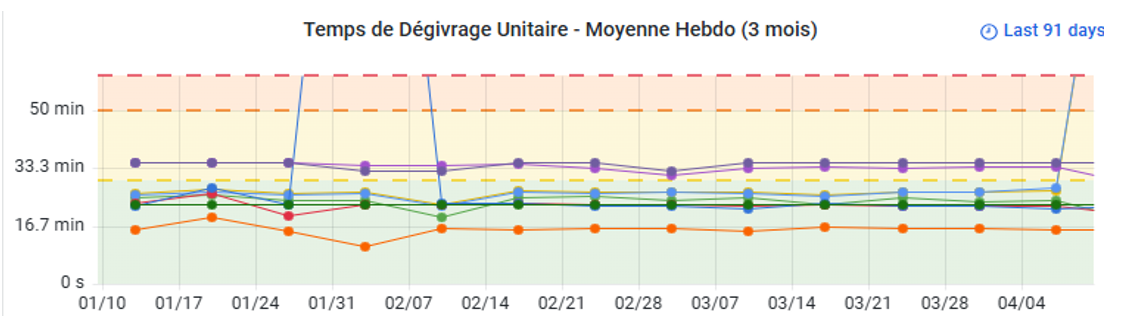

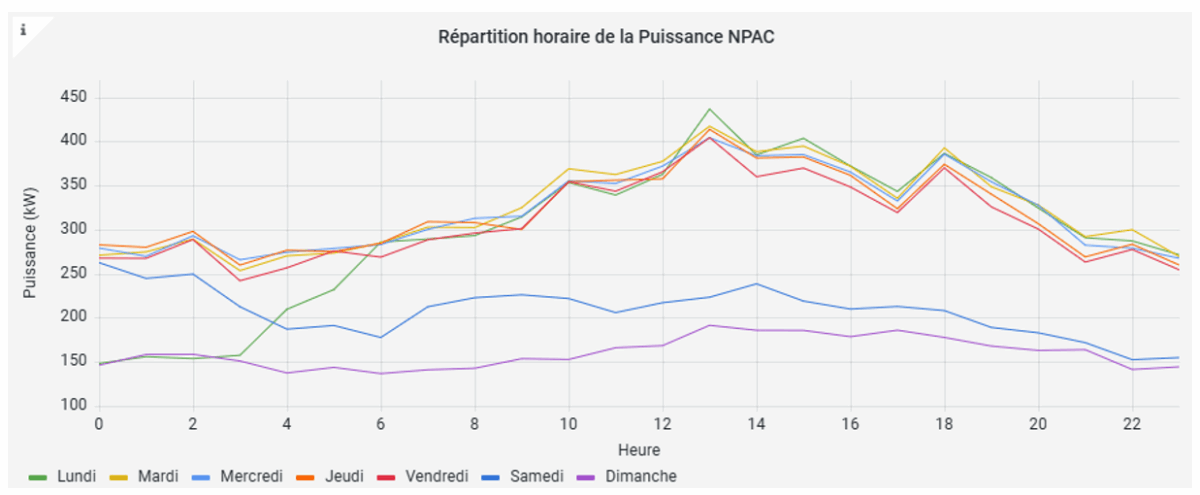

With regard to air handling unit analysis and filter clogging, this is a fairly recurrent problem for the company, and the cost is doubly important: impact on the cost and availability of these filters, accessibility for maintenance operations, and the considerable time spent by technicians in carrying out these pre-programmed interventions. Saint Jean aims to be more proactive and work further upstream to anticipate these operations. By increasing the power of the drive (when this data is available) or, failing that, the percentage of fan operation, it is possible in the long term to define an alert threshold slightly ahead of that proposed by the BMS pressure switches. In addition, the tool can be used to monitor overall energy consumption over the long term, calculating the energy overconsumption induced by this problem and making technicians more aware of their responsibilities (Fig. n°1), as well as to compare parameters over different periods or different equipment (Fig. n°2).

In addition to this monitoring, the data can also be used in other ways: the AHU’s “operating status” data can be used to calculate the time and number of defrosting operations carried out by the units, enabling them to be compared and optimized. These data also appear as reference measurement points in the CMMS, available to technicians.

Energy recovery and reduced environmental footprint

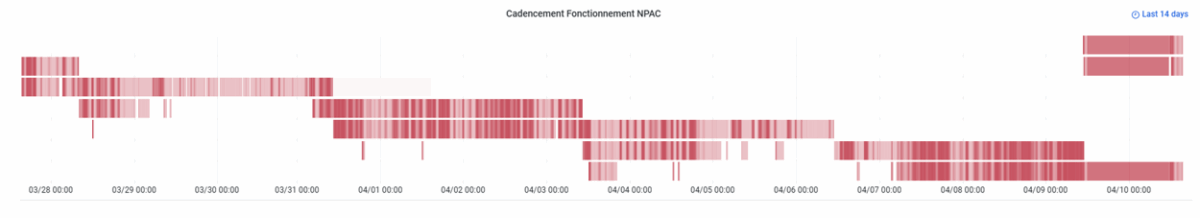

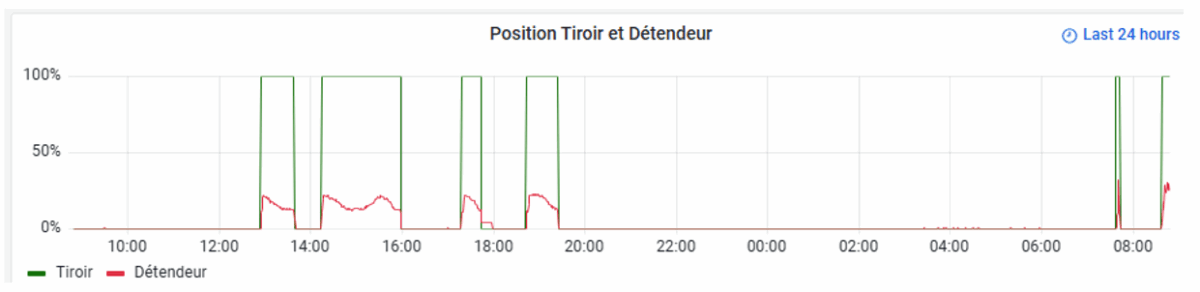

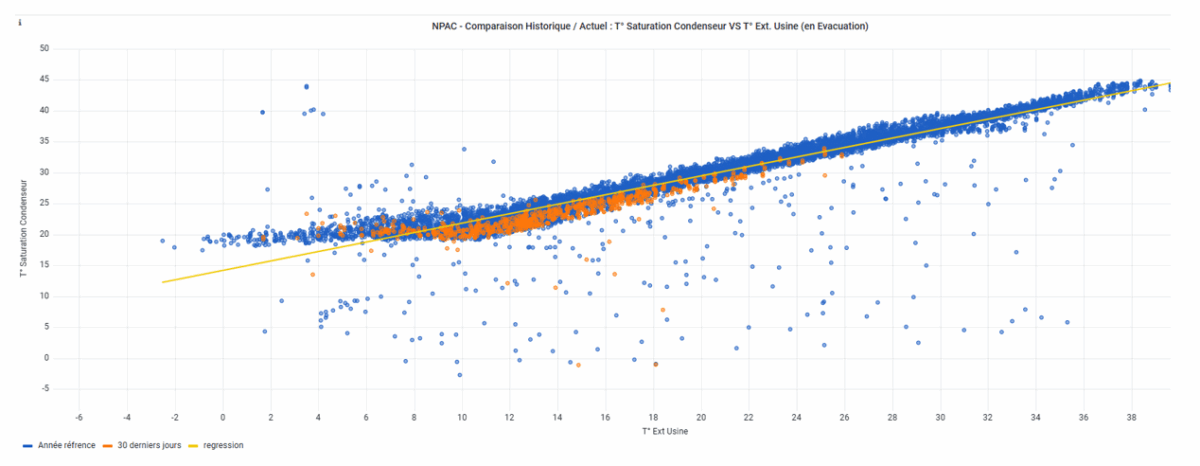

The project has also made it possible to set up longer-term monitoring of energy recovery equipment: cold supply, 7 heat pumps that can work in recovery or evacuation mode, and 14 hot air rejection fan units. This equipment also requires special attention, as it is vital to the company’s production. The tool makes it possible to observe the correct timing of the tools (Fig. n°4), operating times, and untimely stops and restarts which can sometimes occur (Fig. n°5) and require improved settings. Longer-term analyses can also be used to optimize overall system regulation, such as the analysis of condenser saturation temperature as a function of outdoor temperature (Fig. n°7). Other elements complete the BL Predict stack, such as the automatic integration of site weather data, or even pollution levels (presence of pollens around the site), but whose impact was ultimately analyzed as negligible in this case.

To date, data has been collected on over 60 different pieces of equipment and 2 production sites, with 2.3 million pieces of data collected in real time every day. New projects to complement the BMS are currently underway, such as the integration of boiler room and compressed air data, or are scheduled for completion in 2025, such as the vibration monitoring of two mincers and a rolling mill, or the automated monitoring of particles in production areas.

The advantage of the tool and the availability of BL.Predict’s consultant data analysts is that it can give meaning to all plant data, whether purely technical, in which case it will require joint work with the customer’s technical teams, or related to energy consumption, fluids, building or datacenter temperature monitoring, production measurements, or even budget reporting. And its integration with CARL Source CMMS is a major source of automation for monitoring, analysis, alerts and reporting, making it an indispensable tool for tomorrow’s maintenance. For the record, Saint Jean also asked us to set up a storm data monitoring system, which requires us to check the installations and rainfall levels to ensure the watering of its trees during the hot season.