The global economy is shifting toward sustainability, driven by environmental urgency, regulatory demands, and evolving consumer expectations. Businesses are increasingly adopting circular economy principles, moving away from the linear “take, make, waste” model to systems that extend product lifecycles, minimize waste, and optimize resource use [Rejeb et al., 2025].

This transition aligns with the rise of Industry 5.0 (I5.0), which prioritizes sustainability, resilience, and human-centric collaboration. The integration of circular economy and collaborative networks is becoming essential for future-proof asset management, offering both environmental and economic benefits.

Circular Economy: Core Concepts and Frameworks

Circular economy is known as “an emerging mindset that aims for the sustainable use of natural resources, necessitating a shift from the linear model of ‘take, make, use and dispose/waste’ to the circular model of ‘reduce, reuse, recycle, recover, remanufacture and redesign’” [Khan et al., 2021]. As such, this model supports I5.0’s sustainability goals, enhances resilience through modularity and localized production, and fosters human-centricity via collaborative, user-inclusive design.

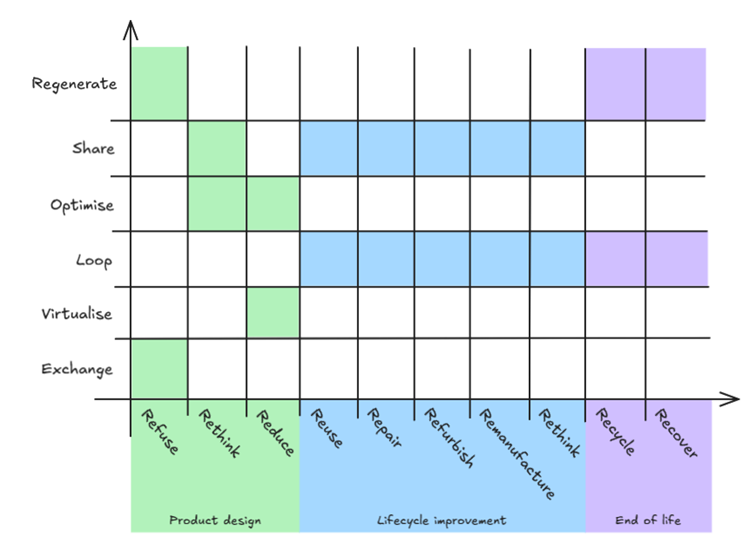

Two key frameworks guide circular economy implementation:

- The 10R Strategies: Evolving from the 1970s’ 3R model (reduce, reuse, recycle), the 10R framework (refuse, rethink, reduce, reuse, repair, refurbish, remanufacture, repurpose, recycle, recover) provides a roadmap for circular innovation (Reike et al., 2018).

- The ReSOLVE Framework: Developed by the Ellen MacArthur Foundation, ReSOLVE outlines six actions—regenerate, share, optimize, loop, virtualize, and exchange—to maximize resource efficiency, extend product lifecycles, and minimize waste.

Collaborative networks: enabling circularity

Circular economy is also deeply connected to the concept of collaborative networks, defined as “composed of a variety of entities—organizations people and even smart machines—which are largely autonomous, geographically distributed, and heterogeneous in terms of their operating environment, culture, social capital and goals… that collaborate to (better) achieve common or compatible goals” [Camarinha-Matos et al., 2024].

Collaborative networks play a pivotal role in advancing the circular economy. They enable cross-sectoral knowledge sharing, resource optimization, and the development of innovative value co-creation strategies. This is achieved through horizontal partnerships, integrated supply chains, and localized ecosystems [Perotti et al., 2025].

Main challenges

However, the development of circularity faces some limits that have been identified in the literature [Jaeger et Upadhyay, 2020]:

- (L1) High initial costs: most industry players surveyed on the subject point out that implementing a circular economy is expensive, but that the return on investment remains unclear.

- (L2) Complexification of supply chains: some of these players mention that the supply chain is becoming more complex with an increase in trade channels, which can be a daunting change.

- (L3) Difficult to establish B2B cooperation: each company has its own system for identifying products, which makes cooperation difficult. In addition, the circular economy involves signing new collaboration agreements between companies whose values are not always aligned.

- (L4) Lack of information on the design and production of the products concerned.

- (L5) Compromises on quality: in some cases, the use of reconditioned components (or recycled materials) may present a risk compared to new components (or materials).

- (L6) Product disassembly is expensive and time-consuming.

Circular Economy in Asset Management

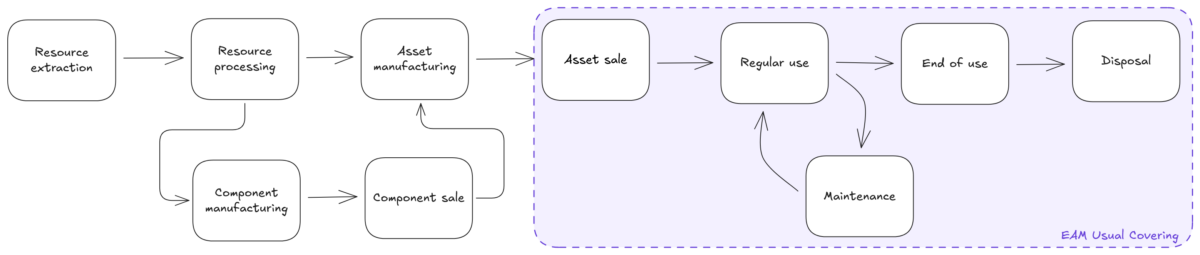

Enterprise Asset Management (EAM) involves strategies and processes designed to maximize the lifespan and productivity of assets. A key component of EAM is the Computerized Maintenance Management System (CMMS), a digital platform that tracks asset conditions throughout their entire lifecycle—from installation to disposal—and stores this data in a centralized database.

Corporate assets, which include physical properties like equipment, vehicle fleets, and buildings, are just as relevant to the principles of the circular economy as any other industrial product.

While most EAM tools focus on managing the asset lifecycle—from acquisition to disposal—they often prioritize maintenance cycles (both preventive and reactive) to ensure optimal performance. However, this approach only addresses a fraction of an asset’s true lifecycle potential.

In the context of enterprise assets, circular economy principles translate into:

- Ensuring that assets last longer

- Designing assets that can be refurbished over several life cycles

- Transitioning to service models

- Creating syndicates, networks or value chains to promote sustainable and circular collaborations

Both EAM and circular economy strategies share a core objective: maximizing the lifespan of assets. However, the circular economy introduces additional dimensions—such as collaborative ecosystems and extended life cycles through refurbishment, reuse, or remanufacturing.

Far from conflicting with EAM’s economic optimization goals, this transition to circular models offers significant advantages: the transition to more sustainable models should enable savings on asset prices (recycled materials, less exposure to raw material price volatility), the development of innovation within companies with new operating methods, the creation of new jobs (particularly in the field of disassembly) and greater system resilience with the possibility of finding replacement assets more easily (within networks or in the case of service models).

Technological Innovations enabling more Circular EAM

Optimizing assets lifecycle

IoT and machine learning can be used for predictive analytics to forecast failures that could damage assets, thereby reducing their lifespan. This analysis can also be used to optimize maintenance cycles, accompanied by operational research to plan interventions, to reduce the workload on technicians without putting assets at risk. Digital twins are also a promising avenue, particularly thanks to simulation capabilities that provide a better understanding of asset behavior.

In addition, the IoT, new means of interaction made possible by AI, and vertical collaborative networks enable the implementation of more complex digital twins, consisting of sets of digital twins (the concept of an ‘industrial metaverse’), to optimize the lifecycle of assets in a more global context.

Assisting complex operations of end-of-life

We have seen that, within the framework of EAM, the ‘end of life’ occurred as soon as the asset left the ‘traditional’ maintenance cycle. But approaches exist to extend the end-of-life coverage.

From the manufacturers’ point of view, rethinking assets to make them more modular and repairable, and from the companies’ point of view, choosing assets designed to be repaired; the concept of additive manufacturing and 3D printing can be particularly useful in facilitating modularity and repairability, while making spare parts more accessible (manufacturing anywhere from plans).

It is also possible to assist with repairs and disassembly using plans and instructions and technologies such as mixed reality, which allows information to be sent during operations, or robotics, which can take on these tasks or simply assist with them (arms to guide the parts to be worked on through the various stages).

Finally, detecting the health status of assets using IoT, machine learning and digital twins, and pushing for the right actions and the right partners to extend their lifespan using horizontal collaborative networks, should also help us move in the right direction.

Ensuring transparent monitoring throughout the life cycle

The vast majority of surveys on the state of the art of the circular economy or sustainable development for I5.0 mention, at one point or another, the use of blockchain technology. This generally involves facilitating communication between stakeholders in the supply chain or ensuring the traceability of a product along that chain, using reliable information-sharing technology.

In practice, this observation reflects a need for transparency and reliability in tracking the life cycle of products. For EAM, this concept becomes crucial when it comes to understanding the origin of equipment and parts, tracking repairs carried out prior to acquisition, the composition of materials, etc. Furthermore, it can be a solution to the limitations of L4 on the issue of provenance and L3 on the difficulty of B2B cooperation.

The concepts conveyed through this monitoring can thus support the two previous areas by feeding into predictive models or providing reliable information to assist end-of-life management.

Conclusion and Road Ahead

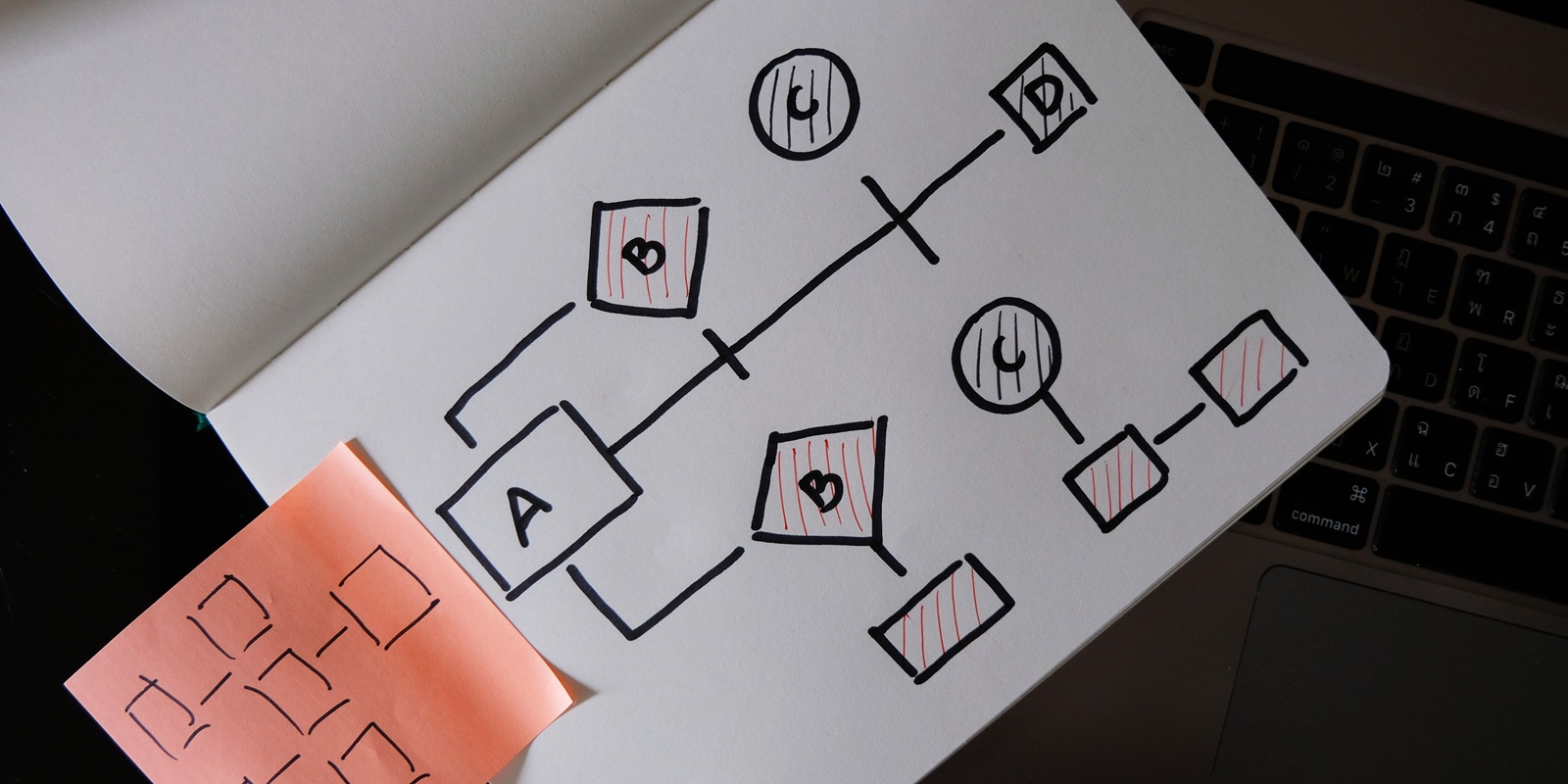

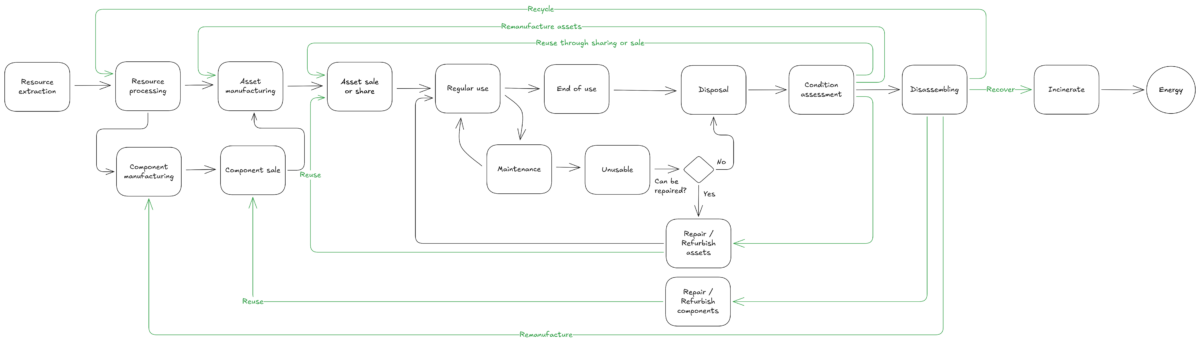

Let’s build a full representation of assets lifecycle based on what have been said previously.

Most of the 10R strategies can be found in this representation, as well as the notions of sharing, looping and optimizing from the ReSOLVE framework. We can also notice that components lifecycles are also considered alongside assets lifecycles. Also, compared to what is usually covered by EAM, this representation adds life extension through condition assessment linked to different circular solutions and end-of-life management with disassembly. Finally, even if it does not directly appear here, there is a strong dependence on logistics to transfer assets and components along the loops.

To ensure EAM can evolve to this extent, various directions can be explored:

- Lifecycle optimization to extend EAM coverage: this could involve using IoT and ML methods to improve the maintenance cycle to optimize equipment usage, but also to extend end-of-life management with condition assessment and disassembly, relying on digital twins, mixed reality, and digital equipment passports (possibly supported by blockchain) to aid diagnosis and disassembly.

- The creation of a horizontal collaborative platform connecting equipment users, manufacturers, transporters and circular economy players (repair, recycling, etc.): this could be a fairly simple directory platform, connected to Carl Source, supporting stock management and with features to facilitate obsolescence management, with a comprehensive and detailed catalogue of parts and equipment.

- Economic and ecological cost optimization for logistics (transport, storage): this could be a solution integrating warehouse optimization and management, route optimization and promoting collaboration between carriers. The solution would therefore be closely linked to the collaborative platform, but with a focus on flows.

References

Khan, Iqra Sadaf, Muhammad Ovais Ahmad, and Jukka Majava. 2021. “Industry 4.0 and Sustainable Development: A Systematic Mapping of Triple Bottom Line, Circular Economy and Sustainable Business Models Perspectives.” Journal of Cleaner Production 297 (May): 126655. https://doi.org/10.1016/j.jclepro.2021.126655.

Rejeb, Abderahman, Karim Rejeb, John G. Keogh, and Edit Süle. 2025. “When Industry 5.0 Meets the Circular Economy: A Systematic Literature Review.” Circular Economy and Sustainability, ahead of print, April 22. When Industry 5.0 Meets the Circular Economy: A Systematic Literature Review .

Reike, Denise, Walter J. V. Vermeulen, and Sjors Witjes. 2018. “The Circular Economy: New or Refurbished as CE 3.0? — Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options.” Resources, Conservation and Recycling, Sustainable Resource Management and the Circular Economy, vol. 135 (August): 246–64. https://doi.org/10.1016/j.resconrec.2017.08.027.

Camarinha-Matos, Luis M., Andre Dionisio Rocha, and Paula Graça. 2024. “Collaborative Approaches in Sustainable and Resilient Manufacturing.” Journal of Intelligent Manufacturing 35 (2): 499–519. https://doi.org/10.1007/s10845-022-02060-6.

Perotti, Francesco Antonio, Ilan Alon, Bhumika Gupta, and Alberto Ferraris. 2025. “Unravelling Inter-Organisational Collaboration to Address the Circular Economy Transitions: A Systematic Literature Review.” Business Strategy and the Environment 34 (8): 10653–80. Unravelling Inter‐Organisational Collaboration to Address the Circular Economy Transitions: A Systematic Literature Review .

Jaeger, Bjoern, and Arvind Upadhyay. 2020. “Understanding Barriers to Circular Economy: Cases from the Manufacturing Industry.” Journal of Enterprise Information Management 33 (4): 729–45. Understanding barriers to circular economy: cases from the manufacturing industry .